Khabone e ka har'a tšepe ke e 'ngoe ea lintlha tsa bohlokoa tse susumetsang ho cheseha ha thepa ea forging. Tšepe, motsoako oa tšepe le k'habone, e ka ba le maemo a fapaneng a khabone, a amang ka kotloloho thepa ea eona ea mochini, ho kenyeletsoa matla, thata, le ductility. Bakeng sa forgings tse cheselitsoeng, ho utloisisa kamano lipakeng tsa khabone le ts'ebetso ea welding ho bohlokoa ho netefatsa bots'epehi le boleng ba manonyeletso a cheselitsoeng.

Litšepe tse nang le khabone e tlase, tseo hangata li nang le k'habone e ka tlase ho 0.30%, ke lisebelisoa tse chesehang ka ho fetisisa. Litšepe tsena li bonts'a ductility e ntle le ho se sebetse hantle, ho li etsa tse loketseng mefuta e mengata ea lisebelisoa tsa welding. Likahare tse tlase tsa khabone li fokotsa kotsi ea ho peperana sebakeng se anngoeng ke mocheso (HAZ) nakong le ka mor'a ho cheselletsa. Lebaka ke hobane maemo a tlase a khabone a fella ka ho thatafala ho tlase, ho bolelang hore thepa ha e na monyetla oa ho theha li-microstructures tse brittle joalo ka martensite, e ka bang bothata libakeng tse cheselitsoeng. Ka hona, li-forging tse nang le khabone e tlase li na le litaba tse fokolang tse amanang le ho phatloha kapa ho sotha nakong ea lits'ebetso tsa welding.

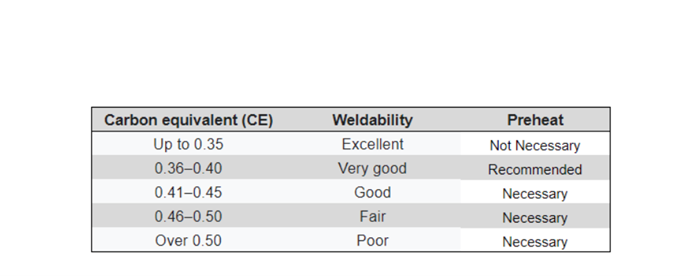

Ka lehlakoreng le leng, ha khabone e ntse e eketseha, ho cheseha ha tšepe hoa fokotseha. Litšepe tse nang le k'habone e bohareng, tse nang le khabone e pakeng tsa 0.30% le 0.60%, li fana ka matla le boima bo phahameng ha li bapisoa le litšepe tse nang le khabone e tlase empa li tla le likotsi tse eketsehileng nakong ea ho cheselletsa. Likahare tse phahameng tsa carbon li lebisa ho thatafala ho hoholo, e leng ho eketsang monyetla oa ho theha mehaho ea martensitic ho HAZ. Li-microstructures tsena li thata ebile li brittle, li phahamisa menyetla ea ho peperana, haholo-holo tlas'a khatello ea maikutlo kapa tšusumetso. Tlhokomelo e khethehileng, joalo ka preheating le post-weld mocheso kalafo, hangata ho hlokahala ha ho tjheseletsa forgings medium-carbon tšepe ho thibela litaba tsena.

Litšepe tse nang le khabone e phahameng, tse nang le khabone e fetang 0.60%, li baka mathata a maholohali a ho cheselletsa. Likahare tse phahameng tsa khabone li eketsa thata ho thatafala ha tšepe le brittleness, e leng se etsang hore e be bonolo haholo ho petsoha nakong ea ts'ebetso ea welding. Maemong a mang, litšepe tse nang le k'habone e phahameng li ka hloka mekhoa e khethehileng ea ho cheselletsa kapa li kanna tsa se tšoanelehe ho cheselletsa ho hang ntle le liphetoho tse kholo tšebetsong. Preheating, taolo ea mocheso oa interpass, le kalafo ea mocheso ka mor'a weld li bohlokoa ho qoba ho hloleha ho brittle ho forgings high-carbon steel.

Ka bokhuts'oane, khabone ea tšepe e bapala karolo ea bohlokoa ho fumana katleho ea ho cheselletsa linthong tse entsoeng. Litšepe tse nang le khabone e tlase ke tsona tse chesehang ka ho fetesisa, athe litšepe tse mahareng le tse phahameng tsa khabone li hloka taolo e hlokolosi haholoanyane ea liparamente tsa tjheseletsa ho thibela likoli tse kang ho peperana. Ho utloisisa litaba tsa khabone le ho khetha mekhoa e nepahetseng ea ho cheselletsa ho bohlokoa bakeng sa ho netefatsa ho tšoarella le ts'ebetso ea liforomo tse cheselitsoeng lits'ebetsong tse fapaneng tsa indasteri.

Nako ea poso: Oct-16-2024