Ts'ebetso ea forgings e bohlokoa lits'ebetsong tse fapaneng tsa indasteri, ho tloha ho likarolo tsa koloi ho ea ho likarolo tsa sefofane. Ho eketsoa ha likarolo tse fapaneng tsa alloy ho ka ama haholo thepa ea thepa e entsoeng, ho matlafatsa matla a bona, ho tšoarella le ho hanyetsa maemo a tikoloho. Sengoliloeng sena se hlahloba tse ling tsa likarolo tsa bohlokoa tsa alloying le hore na li ama ts'ebetso ea forgings joang.

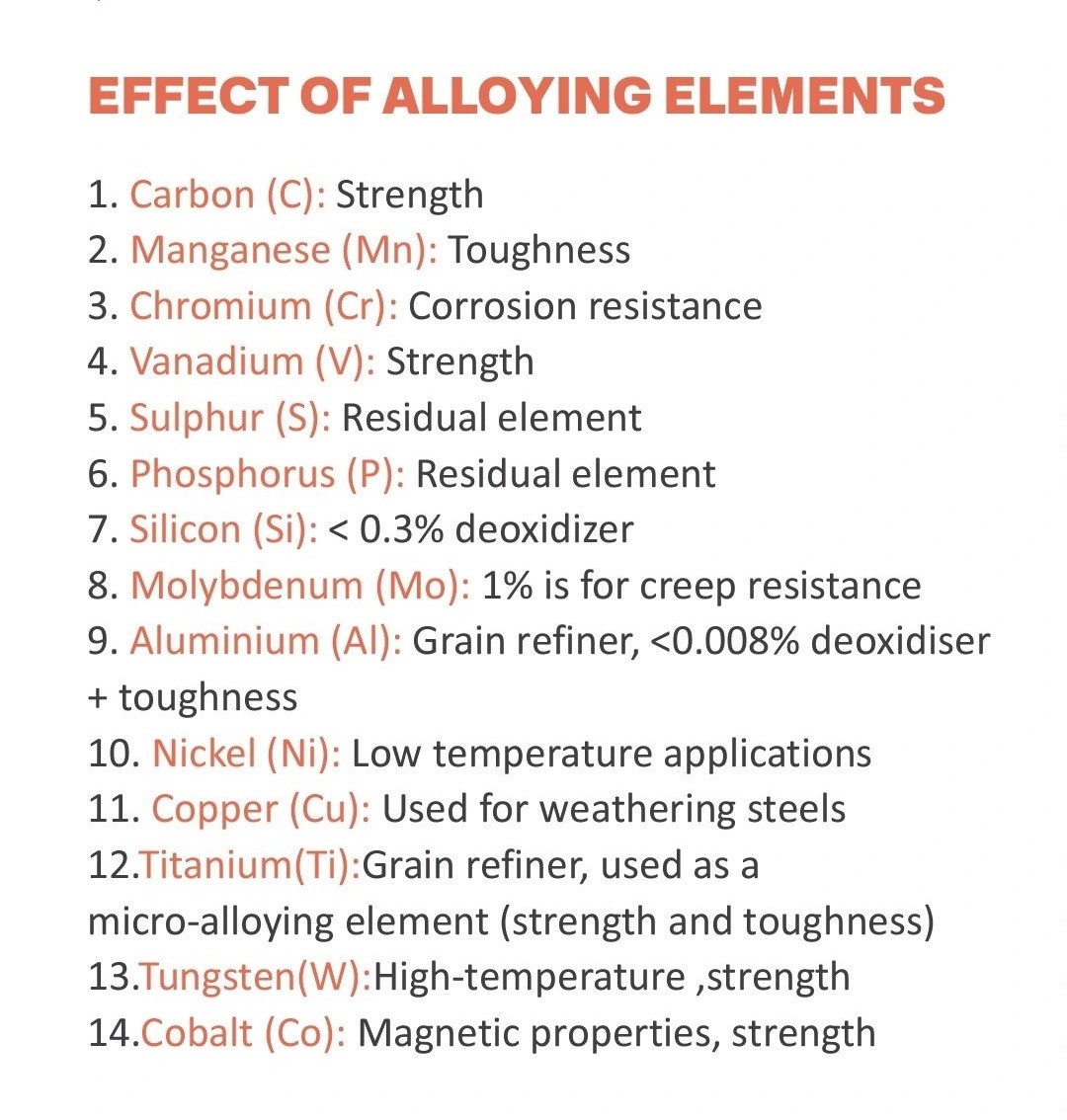

Lintlha tsa Key Alloying le Liphello tsa tsona

Khabone (C):

Carbon ke e 'ngoe ea likarolo tsa bohlokoa ka ho fetisisa tsa alloying ka tšepe. E ama ka ho toba ho thatafala le matla a thepa. Likahare tsa k'habone tse phahameng li eketsa ho tiea le matla a thata a forging, ho etsa hore e tšoanelehe bakeng sa lits'ebetso tse hlokang khanyetso e phahameng, joalo ka lisebelisoa tsa ho itšeha le likarolo tsa koloi. Leha ho le joalo, k'habone e ngata haholo e ka etsa hore thepa e brittle, e fokotsa ho hanyetsa ha eona.

Chromium (Cr):

Chromium e tsebahala ka bokhoni ba eona ba ho ntlafatsa ho hanyetsa kutu le ho ba thata. E etsa lera le sa sebetseng la chromium oxide holim'a metsi, e sireletsang mokelikeli ho tsoa ho oxidation le corrosion. Sena se etsa hore litšepe tse nang le chromium-alloyed li loketse ts'ebeliso ea tikoloho e thata, joalo ka liindasteri tsa leoatle le tsa lik'hemik'hale. Ho feta moo, chromium e ntlafatsa ho thatafala ha tšepe, e e lumellang ho fumana matla le ho tiea ka mor'a kalafo ea mocheso.

Nickel (Ntho):

Nickel e eketsoa ho forgings ho ntlafatsa ho tiea ha bona le ductility, haholo-holo mocheso o tlaase. E boetse e ntlafatsa khanyetso ea thepa ho corrosion le oxidation. Litšepe tse nang le Nickel-alloyed li sebelisoa hangata indastering ea sefofane le oli le khase, moo ho hlokahalang matla a phahameng le ho hanyetsa maemo a thata. Ho ba teng ha nickel ho boetse ho tsitsisa mohato oa austenitic, ho etsa hore tšepe e se ke ea sebetsa ka matla le ho ntlafatsa ts'ebetso ea eona.

Liphello tse Kopantsoeng le Lisebelisoa tsa Indasteri

Motsoako oa lintho tsena le tse ling tsa motsoako, tse kang molybdenum (Mo), vanadium (V), le manganese (Mn), li ka hlahisa lisebelisoa tse nang le thepa e hlophisitsoeng bakeng sa lisebelisoa tse khethehileng. Mohlala, molybdenum e eketsa matla a mocheso o phahameng le ho hanyetsa ha tšepe ea tšepe, e etsa hore e tšoanelehe bakeng sa mahare a turbine le likepe tsa khatello. Vanadium e ntlafatsa sebopeho sa lijo-thollo, e ntlafatsa matla le ho tiea ha ho qhekella. Manganese e sebetsa joalo ka deoxidizer mme e ntlafatsa ho thatafala le ho tiea ha thepa.

Indastering ea likoloi, li-forging tse nang le motsoako o leka-lekaneng oa carbon, chromium, le manganese li sebelisoa ho hlahisa lisebelisoa tse matla, tse sa senyeheng tse kang li-crankshaft le likere. Lefapheng la lifofane, li-alloys tsa nickel le titanium li bohlokoa bakeng sa ho etsa likarolo tse bobebe empa tse matla tse khonang ho mamella mocheso o feteletseng le khatello ea maikutlo.

Qetello

Ts'ebetso ea li-forging e susumetsoa haholo ke ho eketsoa ha likarolo tsa alloying, e 'ngoe le e' ngoe e fana ka thepa e ikhethileng e ntlafatsang ts'ebetso ea thepa ka kakaretso. Ho utloisisa karolo ea likarolo tse kang carbon, chromium, le nickel ho thusa litsebi tsa metallurgist le lienjineri ho rala liforomo tse fihlelang litlhoko tse boima tsa lits'ebetso tse fapaneng tsa indasteri. Ka ho khetha le ho kopanya likarolo tsena ka hloko, bahlahisi ba ka hlahisa lihlahisoa tsa boleng bo phahameng tse nang le matla a phahameng, ho tšoarella, le ho hanyetsa maemo a tikoloho, ho netefatsa ho tšepahala le ho phela nako e telele lits'ebetsong tsa bona.

Nako ea poso: Jul-30-2024