Litaba tsa indasteri

-

Ke mekhoa efe ea tlhahlobo e sa senyeheng e loketseng liforomo tse kholo

Ultrasonic Testing (UT): Ho sebelisa melao-motheo ea ho phatlalatsoa ha ultrasonic le ho nahanisisa ka thepa ho lemoha mefokolo. Melemo: E khona ho lemoha mefokolo ea ka hare ho forgings, joalo ka pores, inclusions, cracks, joalo-joalo; Ho ba le kutloisiso e phahameng ea ho lemoha le ho nepahala ha boemo; Moqapi oohle o ka ...Bala haholoanyane -

Ho futhumala ha likarolo tsa tšepe

Tempering ke mokhoa oa ho phekola mocheso oo workpiece e timang 'me e futhumetse mocheso o ka tlase ho Ac1 (mocheso oa ho qala oa pearlite ho austenite phetoho nakong ea mocheso), o tšoaroa ka nako e itseng, ebe o pholile mocheso oa kamore. Hangata ho tsitsa ho latela ...Bala haholoanyane -

Melemo ea ho etsa forgings ka 4145H ke efe?

4145H ke tšepe e hlophisitsoeng e sebelisoang haholo ho etsa le ho sebelisa lisebelisoa tsa ho cheka liliba tsa oli. Tšepe e sebetsoa ka seboping sa arc ebe e sebetsoa ka theknoloji ea ho hloekisa e bonolo. Ho feta moo, hangata li-drill tsa oli li sebelisoa ho ntlafatsa ts'ebetso ea likotoana tsa ho cheka. Ha o sebelisa tšepe ea 4145H ka dir ...Bala haholoanyane -

Khetha 4145H kapa 4145H MOD bakeng sa stabilizer

4145H le 4145H MOD ke lintlha tse peli tse fapaneng tsa tšepe tse sebelisoang haholo-holo bakeng sa lisebelisoa tsa matla a phahameng le mocheso o phahameng indastering ea peterole le ea khase ea tlhaho. Liphapang tsa bona li maemong a latelang: Sebopeho sa lik'hemik'hale: Ho na le phapang e nyane ea sebopeho sa lik'hemik'hale b...Bala haholoanyane -

Phekolo ea ho tima le ho kokobetsa

Phekolo ea ho tima le ho futhumatsa e bua ka mokhoa o habeli oa kalafo ea mocheso oa ho tima le mocheso o phahameng oa mocheso, o ikemiselitseng ho netefatsa hore sesebelisoa se na le thepa e ntle ea mochini. Mocheso o phahameng oa mocheso o bolela ho futhumatsa pakeng tsa 500-650 ℃. E matla haholo ebile e khutsitse ...Bala haholoanyane -

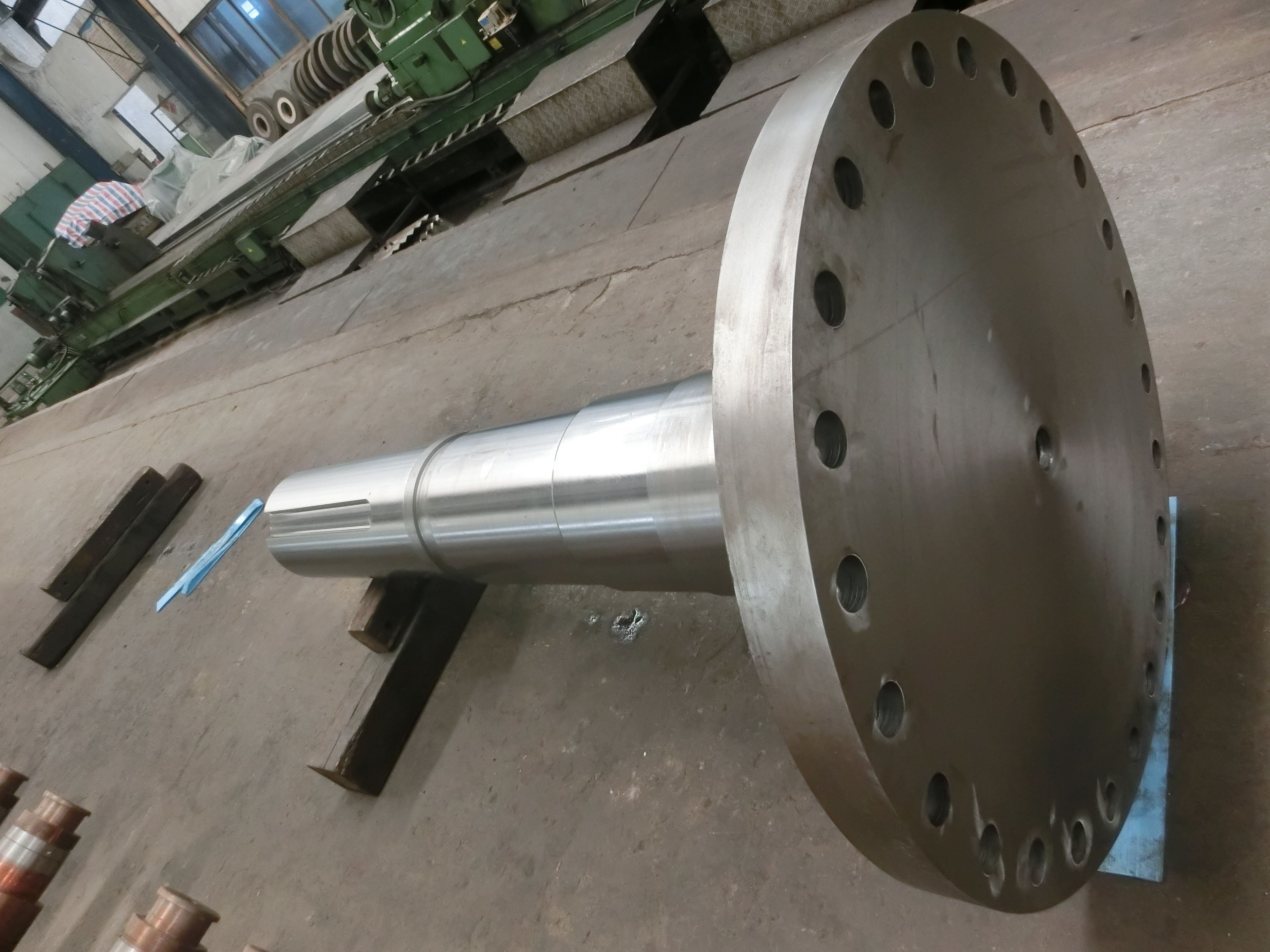

Li-Shaft Forgings bakeng sa Li-turbine tsa Hydraulic le Lijenereithara tsa Hydraulic

1 Ho qhibilihisa 1.1 Ho qhibilihisa alkaline sebōpi sa motlakase ho lokela ho sebelisoa bakeng sa ho etsa litšepe. 2 Forging 2.1 Chelete e lekaneng ea ho itšeha e lokela ho ba teng lipheletsong tse ka holimo le tse ka tlaase tsa ingot ea tšepe ho etsa bonnete ba hore sengoathoana se entsoeng ha se na likoti tsa shrinkage le karohano e matla. 2.2 Ho qhekella ...Bala haholoanyane -

Likarolo tse bulehileng tsa forging

Mekhoa ea mantlha ea ho forging mahala e kenyelletsa ho ferekanya, ho lelefatsa, ho otla ka litebele, ho kobeha, ho sotha, ho falla, ho itšeha le ho qhekella. Free forging elongation Elongation, eo hape e tsejoang e le katoloso, ke mokhoa oa ho forging o fokotsang karolo e ka holimo ea billet le ho eketsa bolelele ba eona. Elong...Bala haholoanyane -

Ho theha rotor ea li-turbine tsa mouoane oa indasteri

1. Smelting 1.1 Bakeng sa tlhahiso ea likarolo tse entsoeng ka maiketsetso, ho qhibiliha ha sebōpi sa alkaline sa arc e lateloang ke ho hloekisa ka ntle ho buelloa bakeng sa li-ingots tsa tšepe. Mekhoa e meng ea ho netefatsa boleng le eona e ka sebelisoa bakeng sa ho qhibilihisa. 1.2 Pele kapa nakong ea ho akheloa ha li-ingots, tšepe e lokela ho theoleloa ...Bala haholoanyane -

Ho tloaeleha ha karolo ea forging

Normalizing ke phekolo ea mocheso e ntlafatsang ho tiea ha tšepe. Kamora ho futhumatsa lisebelisoa tsa tšepe ho mocheso oa 30-50 ℃ ka holimo ho mocheso oa Ac3, li tšoare nako e itseng 'me moea o li pholisoe ka ntle ho sebōpi. Sebopeho sa mantlha ke hore sekhahla sa ho pholisa se potlakile ho feta Anne...Bala haholoanyane -

Tse ling tsa Technical Spec Bakeng sa li-flange tsa tora tse hahiloeng tsa turbine ea moea

Litlhoko tse Akaretsang Likhamphani tsa tlhahiso ea Flange li tlameha ho ba le bokhoni ba tekheniki, bokhoni ba tlhahiso, le tlhahlobo le bokhoni ba tlhahlobo bo hlokahalang bakeng sa lihlahisoa, hammoho le bonyane lilemo tse peli tsa boiphihlelo indastering ea boqapi. Lisebelisoa tsa ho Etsa Lintho Flange manufactu...Bala haholoanyane -

brittleness ea bohale nakong ea ho qhekella le ho sebetsa ha forgings

Ka lebaka la boteng ba brittleness ea khalefo nakong ea ho qhekella le ho sebetsa ha forgings, mocheso o teng oa mocheso o fokotsehile. Ho thibela brittleness hore e se ke ea eketseha nakong ea mocheso, hoa hlokahala ho qoba mekhahlelo ena e 'meli ea mocheso, e leng se etsang hore ho be thata ho fetola prop ea mochini ...Bala haholoanyane -

Mekhoa ea ho futhumatsa shaft forgings ke efe?

Ho futhumatsa ho sa khaotseng ho sebelisoa hangata bakeng sa ho futhumatsa li-shaft forgings, athe ho futhumatsa ho timang maqhubu a phahameng hangata ho kenyelletsa ho lokisa inductor ha forging e ntse e tsamaea. Ho futhumala ha maqhubu a mahareng le maqhubu a matla, hangata a tsamaisoa ke li-sensor, 'me forging le eona e ka potoloha ha ho hlokahala ...Bala haholoanyane