Customized Open Forging Karolo Bakeng sa Bit

Monyetla o tloahelehileng oa ho qhekella

• Ho qhekella ho feta mekhoa e meng ea tlhahiso ho kenyelletsa matla a maholo, ho tšepahala, le ho tšoarella, hammoho le bokhoni ba ho hlahisa libopeho tse rarahaneng tse nang le mamello e thata.

• Bobeli ba forging boholo le sebopeho li customized.

• Forging stock stock e fumaneha ho ipapisitsoe le bongata bo hlokahalang le moralo.

• Leloala la tšepe la lintho tse bonahalang le hlahlojoa ka lilemo tse peli 'me le amohetsoe ke k'hamphani ea rona ea WELONG.

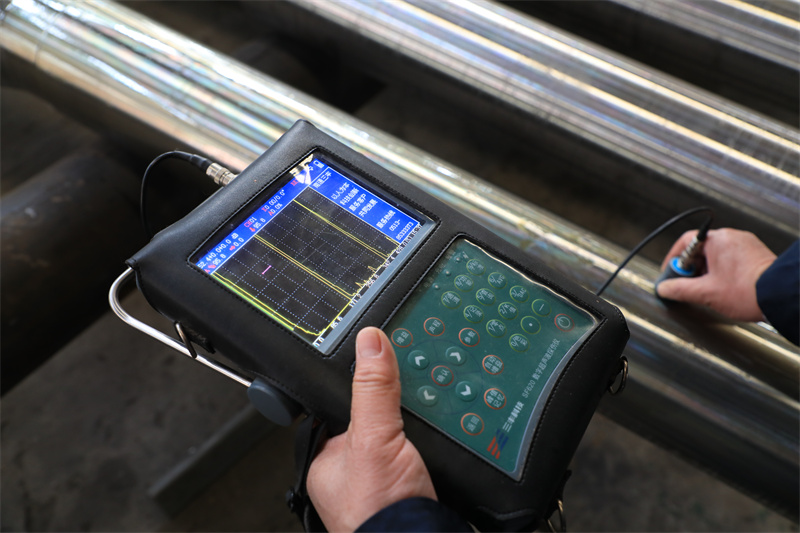

• Stabilizer e 'ngoe le e' ngoe e na le tlhahlobo ea makhetlo a 5 e sa senyang (NDE).

Boitsebiso bo ka Sehloohong

• AISI 4145H MOD, 4330,4130,4340,4140,8620 le joalo-joalo.

Tshebetso

• Forging + Rough machining + Heat Treatment + Property Self Testing + Teko ea motho oa boraro + Finishing Machining + Tlhahlobo ea ho qetela + Ho paka.

Kopo

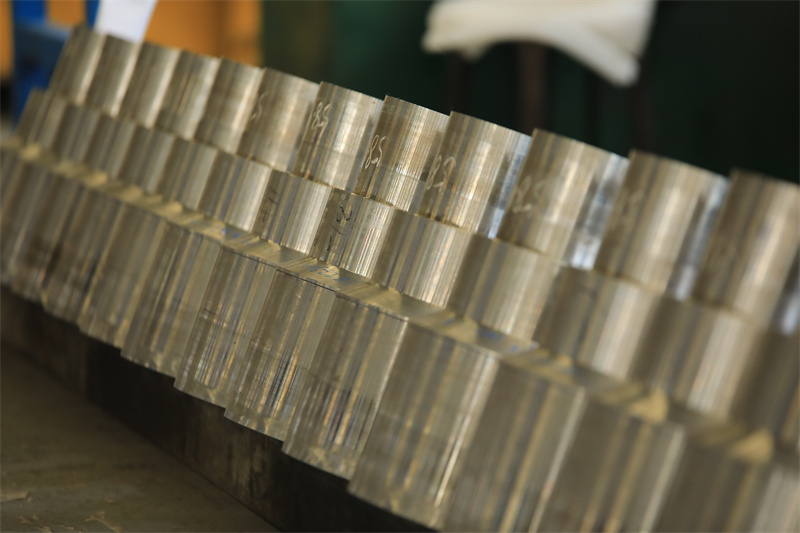

• Motor stabilizer forging, stabilizer forgings, bit forgings, forging shaft, forging ring le tse ling.

Boholo ba ho qapa

• Boima ba ho forging bo ka bang 20T.Bophara ba forging bo boholo bo ka bang 1.5M.

Mokhoa o ikhethileng oa ho qhekella hanyenyane

• Ho futhumatsa: Karolo ea tšepe, eo hangata e leng sebopeho sa bar kapa billet, e futhumatsoa ka mocheso o loketseng ho etsa hore e khonehe.Mocheso ona oa fapana ho itšetlehile ka tšepe e khethehileng e entsoeng.

• Ho Beha le ho Lokisetsa: Mosebetsi o futhumetseng o behoa holim'a anvil kapa holim'a sephara, ho netefatsa ho lumellana hantle bakeng sa ts'ebetso e latelang ea forging.

• Ho Tema ka Hamore: Setei sa tšepe se sebelisa mefuta e sa tšoaneng ea lihamore, tse kang hamore ea matla kapa hamore ea letsoho, ho otla le ho bōpa tšepe.Ho otla ha hamore, ho kopantsoe le ho qhekella ka boqhetseke, ho holofatsa mosebetsi hore e be sebopeho se batloang.

• Ho futhumatsa hape: Ho itšetlehile ka thepa ea tšepe le ho rarahana ha sebopeho se lakatsehang, mosebetsi o ka 'na oa hloka ho futhumatsoa ka makhetlo a mangata nakong ea ts'ebetso ea ho fereka ho boloka ho senyeha ha oona.

• Qetella: Hang ha sebopeho se lakatsehang se fihletsoe, ho ka etsoa mesebetsi e meng e kang ho kuta, ho kuta, kapa ho qetela.